Circular Economy: what is it

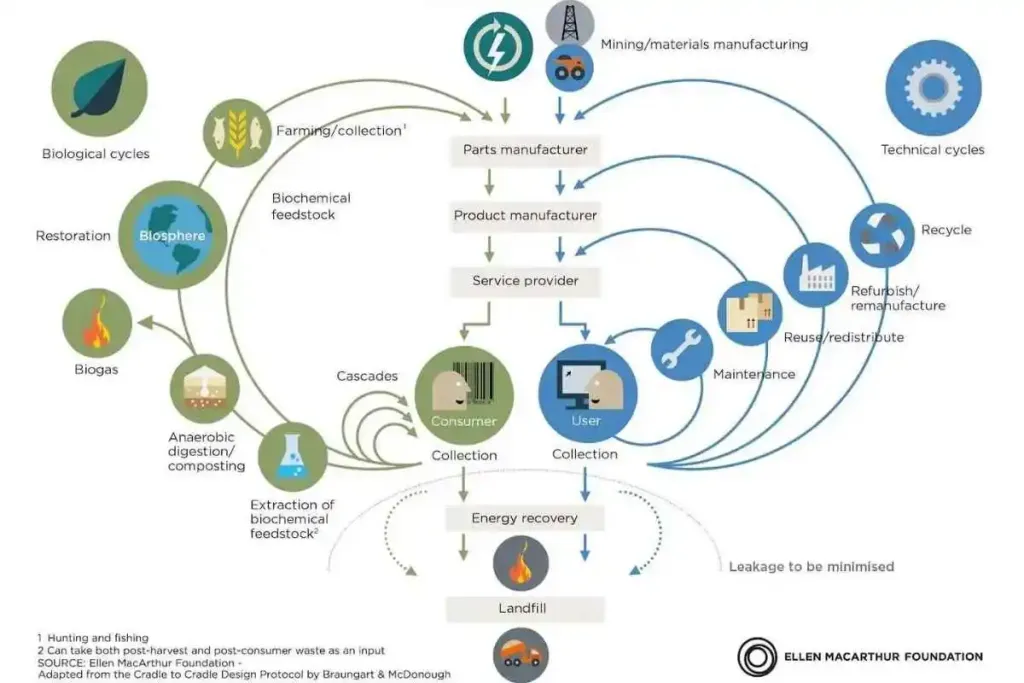

The term Circular Economy refers to a regenerative economic model that applies the concept of reuse to reduce waste and introduces new principles of material and energy management. It is a well-planned and organized system based on collaboration, shared dialogue, and symbiosis among various stakeholders, with a shared commitment to maximizing the value of each utilized material.

Definition and principles of Circular Economy

Circular Economy, also known as EC, is often referred to as the ‘fourth industrial revolution’, representing a fundamental paradigm shift that overturns the values and management of linear economic systems derived from the first industrial revolution, which dominated the 20th century.

This system is not focused on the massive extraction of virgin raw materials, the use of these resources, and a fast and inexorable end-of-life. Instead, it is based on a circular development that takes into account five macro principles:

- Servitization of products and ownership, commonly referred to as PaaS (Product as a Service)

- Sustainable and innovative materials (neo-materials)

- Sharing of property (sharing economy)

- Product regeneration and reconditioning

- Product life extension

Origins of the term Circular Economy

The concept of the Circular Economy is not recent. In fact, the first studies and testimonies by academics and experts were published as early as the 1970s.

However, this sector still remains unknown and challenging for many, hindering its widespread adoption. According to the Ipsos survey ‘Circular Economy in Italy,’ four out of ten Italians are familiar with the basic principles, while only two out of ten can effectively relate them to the definition of Circular Economy.

History of Circular Economy

To gain a better understanding of the origin of the term and the evolution of thinking about this economic model, let’s trace together the most significant steps that led to the creation of the model that promotes a new industrial revolution.

Origins and conceptual development of Circular Economy

- After World War II, the countries involved in the conflict began to understand the connection between ecological and economic thinking. This understanding fostered the emergence of the first research centres and brought these topics into the political debate.

- In 1966, Kenneth Boulding, an English economist, pacifist, and poet naturalized in the United States, introduced the concept of the Earth as a spaceship with limited resources and possibilities in his book ‘The Economics of the Coming Spaceship Earth’. According to Boulding, mankind had to make the best use of and carefully guard what was made available in order to ensure survival.

- In 1971, Barry Commoner, an American biologist and politician, wrote ‘The Closing Circle’, establishing the initial solid foundation of the scientific and technical theory behind the concept of Circular Economy.

- In 1976, Genevieve Reday-Mulvey became the first expert whose report to the European Commission gave a more modern meaning to the term Circular Economy. Her report highlighted both the economic benefits of Circular Economy, including the associated increase in employment, and its competitiveness.

- In 1982, Walter Stahel, a Swiss architect, established the Product-Life Institute, an independent non-profit institute dealing with sustainability strategies and policies to explore new circular systems. With Stahel, the first concepts and business models of Circular Economy were established, such as Product as a Service (PaaS) and the Performance Economy concept.

Insights and key contributions to Circular Economy

- In 2002, William McDonough, an American architect, and Michael Braungart, a German chemist, published the book “Cradle to Cradle“. This milestone of Circular Economy clearly and specifically designates the distinction between circular and linear economy, focusing on the difference between eco-efficiency and eco-effectiveness.

- More recently, in 2009, the most influential non-profit institution dedicated to the Circular Economy and its developments was founded: the Ellen MacArthur Foundation.

The role of the Ellen MacArthur Foundation

When it comes to Circular Economy, it is crucial to mention the Ellen MacArthur Foundation (EMF), the largest and most influential non-profit organization dedicated to this field, operating and focusing on it.

The EMF (Ellen MacArthur Foundation), established in 2009 by its namesake and current president, Ellen MacArthur, is actively dedicated to promoting the development of Circular Economy systems. Operationally, the foundation strives to fulfill its mission by working on two main fronts:

- On the one hand, it supports companies and educational institutions to accompany them in their green transition processes.

- On the other hand, it promotes environmental sustainability to educate its stakeholders through the publication of reports, resources, and the organization of events.

Definition according to EMF

According to the Ellen MacArthur Foundation – named after its founder and president, Ellen MacArthur – the term defines “an economy designed to regenerate itself. In a circular economy, material flows are of two types: biological ones, capable of being reintegrated into the biosphere, and technical ones, destined to be regenerated without entering the biosphere. The circular economy is thus a system in which all activities, starting with extraction and production, are organised so that someone’s waste becomes a resource for someone else. In the linear economy, on the other hand, once consumption ends, the cycle of the product that becomes waste also ends, forcing the economic chain to continuously repeat the same pattern: extraction, production, consumption, disposal.”

EMF Publications

Today, the EMF serves as the benchmark for all those seeking to approach EC issues in a practical manner, leveraging its network of partner companies to organize engaging initiatives and publishing in-depth reports such as “Towards a Circular Economy 2.0” and “Growth Within: A Circular Economy Vision for a Competitive Europe”.

The R-strategy in Circular Economy

One of the key principles underlying EC is the concept of “R strategies”. These encompass a series of actions aimed at promoting the implementation of circular strategies related to product and by-product design and utilization.

The ‘R strategies’ are summarised in a framework consisting of a list of ten actions (‘R-lists’). These are divided into three macro areas themselves:

- use and production of smart products

- extension of the useful life of the product and its parts

- useful application of materials

However, the number becomes greater considering possible combinations of different actions to create new strategies.

These actions were also instrumental in the creation of the most important pieces of waste management legislation: both in Italy, with the Ronchi Decree, and in Europe with Directive 2008/98/EC.

Use and production of smart products

In the first category are the actions that enable the design and subsequent realisation of a product from an Ecodesign perspective. The applicable strategies in this case are:

- Refusing – avoiding the inappropriate use of a product and instead seeking equivalent functionality through a radically different product. An example of this is the use of multi-functional products.

- Rethinking – making intensive use of the product, reconsidering it, and adopting innovative eco-efficient and eco-effective management practices such as sharing economy services.

- Reduce – to be more efficient in the production and use of the product by reducing the use of natural resources or virgin materials.

Extension of product and part life

The objective is to extend the product’s lifespan (life extension) by exploring alternative uses once the item has fulfilled its primary function. Within this strategic area, the possible actions include:

- Re-use – comprehending how a discarded product, deemed no longer functional but in excellent condition, can serve its purpose once again for another consumer.

- Repair – employing and exchanging skills to repair a non-functioning object, ensuring its proper functionality.

- Refurbish – understanding the techniques to revitalize an outdated product, ensuring its suitability for modern consumer needs.

- Remanufacture – repurposing products or their components to create a new product that retains the same functionalities.

- Repurpose – reusing products or their parts to create a new product with varied functionality.

Useful application of materials

In the last segment covered by “R strategies,” we discover methods to maximize the usefulness of materials after their life cycle concludes. The two activities to be implemented in this scenario are:

- Recycle – recycling materials enables the extraction of new raw materials that can be utilized, maintaining comparable or reduced quality.

- Recover – extracting the energy enclosed within materials by incinerating them represents a method to generate fresh value from non-utilizable material.

Business Models in Circular Economy

Four fundamental business models form the bedrock of the Circular Economy. These models have gained prominence as effective tools for validating innovative circular products or services developed by companies and start-ups. These four models are:

- Product as a Service

- Chain Regeneration

- Upcycling

- Product Life-extension

Within each cluster, specific sub-models have been developed to practically determine the implementation of these models. These thirteen micro-clusters, collectively, serve as the blueprint for creating and launching innovative products/services in the market.

Product as a Service (PaaS)

Service Provider Model – in this business model, the seller acts as a service provider, while the buyer opts for borrowing instead of ownership. This model closely resembles a “rental” agreement, where the emphasis is on acquiring the product’s performance rather than ownership.

PaaS aims to minimize product consumption through the promotion of shared utilization, empowering the producer with complete control over the product, including its end-of-life management.

The buyer therefore does not possess the object, but does have access to the performance of the object. Some examples of this model are:

- rental

- performance agreement

- price per use

- exchange of use

There are several interesting case studies to understand how Product as a Service works, such as Ikea and MoBike.

Product Life Extension

This model is based on the recovery and reconditioning of products to make them usable and marketable again.

Emphasis is placed on enhancing the value of product components and discovering novel applications by combining them with other elements, contributing to waste reduction – particularly in the context of Waste Electrical and Electronic Equipment (RAEE). A noteworthy example of this approach is demonstrated by Caterpillar, the esteemed American enterprise, renowned for its remanufacturing of engine blocks.

Examples of this model are:

- durability

- regeneration

- recharge

- buyback

- upgrade

Material Upcycling

This innovative business model revolves around unlocking new value from a discarded product, which would typically end up in a landfill or recycling facility, through creative transformations that render it beneficial for alternative purposes beyond its initial design.

By harnessing the power of upcycling, one can effectively multiply the value of waste items or products, like pallet, while simultaneously eliminating the need for disposal.

In order to create a virtuous system of upcycling, it is possible to operate on two chains:

- Industrial process in which waste is used to produce higher value products.

- Creative craft process, where poor materials are used for more noble purposes such as design and art.

Chain regeneration

Remanufacturingis that set of activities aimed at reducing waste by reengineering certain subgroups of unused products.

The primary goal of this model is to manufacture objects that exhibit high-quality performance by leveraging technological innovations throughout the production processes. A noteworthy characteristic of these novel products is their repairability, as they can be fixed using components sourced from other products.

The schemes that are part of this model are:

- leasing

- repairing

- rigeneration

Turn your company waste into value

Sfridoo® empowers you to harness the residual value of your waste, enabling you to achieve economic, fiscal, and environmental benefits. Embrace the principles of the Circular Economy and collaborate with other companies in our network to maximize your gains.

enhance value nowDifference between Circular and Linear Economy

The fundamental aspect that distinguishes the Circular Economy’s new economic processes from conventional systems is the shift in paradigm.

We have long been accustomed to adhering to a rigid linear progression in the utilization of materials.

This linear trend is summarised by the term ‘take-make-use-dispose’.

Over time, it has become apparent that this pattern cannot be reproduced on a global scale, as it would lead to the generation of an unmanageable amount of waste and garbage, impossible to manage.

Moreover, take-make-use-dispose methods depend on the idealistic notion of limitless availability of resources and energy.

To address this situation, the initial systems incorporating the principles of EC were created, with the intention of converting this linear production concept into a closed-loop framework.

Within the industry, the term Cradle-to-Cradle is commonly employed – leading to the well-known product certification. This signifies how the utilized resource, upon completing the process, reverts back to its origin, generating fresh value.

It is thus essential to advocate and encourage this economic model, which effectively utilizes all phases (design, production, consumption, end-of-life) to constrain the utilization of materials and energy and reduce waste and losses.

The Circular Economy Market

In recent years, the role of Circular Economy has gained increasing importance, thanks to significant investments and strategic visions from major corporations and government entities.

Investments have been channeled into concrete actions to tackle various challenges faced by modern society, such as the pervasive issue of consumerism, the prevalence of mass-produced goods with short lifespans, inadequate resource management, and the need to modernize production systems.

The Statistics of Circular Economy

To grasp the full extent of the paradigm shift being ushered in by Circular Economy in the market and our daily lives, here is a concise overview of the numerical indicators showcasing the transformative power of Circular Economy in delivering economic growth and community advantages.

As stated in the report “No Time to Waste” by Bank of America Merrill Lynch, the worldwide waste production reaches a staggering 11 billion tonnes annually. Shockingly, 75% of this waste is disposed in landfills or incinerators, leaving only a mere 25% to be repurposed or recycled.

Based on estimations concerning the future demand for industrial raw materials, it is predicted that the disparity between commodity demand and supply will amount to approximately 8 billion by 2030, with a staggering rise to 29 billion by 2050.

According to the Agi source, there has been a 117% increase in commodity prices in the last months of 2021.

According to the Ref Research Laboratory, there has been an average 40% increase in the cost of disposing of industrial waste, over the past two years, with the manufacturing industry being the sector most affected by these price hikes.

Economic opportunities

The Ellen MacArthur Foundation reports that the value of unused and idle assets (objects) stored in disused spaces has reached a staggering amount of $630 billion.

The Gen Consulting Company forecasts that the global Circular Economy market will reach a value of $657 million by the end of 2027, with a CAGR (compound annual growth rate) of 7.8%.

According to the European Commission, by 2030, the creation of new jobs resulting from circular models is estimated to be around 700,000 (including 190,000 in Italy). This is projected to lead to a 0.5% increase in GDP and annual savings of €72 billion for companies.

Circular Economy in Europe

Since 2015, the year the Paris Agreement – a global agreement among member states of the United Nations Framework Convention on Climate Change – was signed, the European Commission has promoted several initiatives related to the Circular Economy and waste management.

The most significant one to remember is the Circular Economy legislation package, which mandates that member countries recycle at least 65% of municipal waste and 75% of packaging waste, while setting a 10% limit on waste destined for landfills.

These obligations, as stated in the legislation, are expected to take effect from 2030 and are currently under review by the European Parliament, where the main challenge will be to achieve alignment among countries at different stages of sustainability-related processes integration.

Within the EU, there exists a significant disparity in circular economy practices and models in this regard.

For instance, countries like Germany, Austria, and Italy already recycle 66% of waste, whereas states like the Czech Republic fall short of 30%.

Circular Economy Package: what it is

The Circular Economy Action Plan is a document developed by the European Commission in 2015, outlining a comprehensive action plan consisting of 54 actions aimed at accelerating the transition towards a European Circular Economy.

The Circular Economy Action Plan serves as the foundational document for the development of this sector across Europe and provides guidance to member countries in achieving the set targets by 2030.

What the Circular Economy Action Plan envisages

The actions outlined in the Circular Economy Action Plan are categorized into six intervention areas:

- Actions to make products marketed within the European Union more sustainable and compliant with regulations.

- Activities aimed at raising awareness and empowering consumers and public purchasers.

- Increased focus on sectors that heavily utilize resources and possess high potential for circularity, including electronics and ICT, batteries and vehicles, packaging, plastics, textiles, construction and buildings, food, water, and nutrients.

- Ensuring waste reduction at both urban and industrial levels through citizens’ behavior in handling purchased products and optimization of production processes.

- Promoting circular and conscious behavior among individuals and implementing circular and sustainable policies at the regional and city levels.

- Direct all the listed activities towards the ultimate goal of constructing an economy within the European Union that adheres to the principles of the Circular Economy.

The New Action Plan adopted by the European Parliament

On February 11, 2021, the new Circular Economy Action Plan was amended and approved with a significant majority within the Commission.

This update of the document became possible due to the shared values and objectives related to the Circular Economy among the member states of the Union.

Indeed, according to the European Parliament and its members, Circular Economy is “the path that the EU and businesses must follow to remain innovative and competitive in the global market while simultaneously reducing their environmental impact.”

Differences with the previous Plan

New Circular Economy Action Plan distinguishes itself from the previous one by placing greater emphasis on three particular activities that are currently less developed compared to other aspects:

- the reduction of the consumption footprint

- the increased use of circular materials

- supporting economic growth

The new document includes a new directive on eco-design to encompass non-energy-related products.

This aspect has been included with the aim of standardizing goods entering the market that meet specific criteria regarding durability, non-toxicity, recyclability, and repairability.

What is the European Green Deal

The European Green Deal, or European Green Pact, encompasses a set of policy actions formulated by the European Commission, with the objective of achieving climate neutrality (carbon neutrality) by 2050.

If promptly achieved, this ambitious milestone would position Europe as the first carbon-neutral continent.

The new plan entails several targets, with the most significant ones being:

- Reducing greenhouse gas emissions produced by EU countries by 50% by 2030, and reducing emissions by 55% compared to 1990 levels.

- Revising all regulatory texts pertaining to climate-related matters and introducing a series of new laws on Circular Economy that address biodiversity, agriculture, innovation, and various other areas.

EU proposals for sustainable products

To provide legislative support for the Green Deal and all initiatives related to the adoption of circular models, the European Commission has approved a series of new laws.

This package of legislation, known as the Circular Economy Package, is divided into six thematic areas:

- sustainable and Circular Textiles Strategy

- ecodesign working plan

- global action

- new rules to empower consumers for the green transition

- support for circular business models

- complementary sectoral rules on construction and other product categories (e.g., batteries, chemicals, packaging).

Circular Economy in Italy

When discussing Circular Economy and waste management in Europe, Italy stands out as one of the most virtuous countries in terms of end-of-life object management, even though there is little improvement in terms of innovation regarding reuse and ecodesign.

As highlighted in a study by the Circular Economy Network (CEN), Italy leads in this sector compared to countries such as France, Germany, Spain, and Poland.

Over time, Italy has successfully transformed challenges within its production system into real opportunities. Two main drivers have played a crucial role:

- The need for greater transparency in production processes, including the number of resources utilized and waste disposal methods, to combat illegal waste activities.

- The need to achieve independence in terms of raw material supply by reusing existing resources, thereby reducing dependence on foreign supplies and optimizing production costs, benefiting both businesses and citizens.

Data from the strategic plan

To acknowledge Italy’s commitment to this sector, we share some noteworthy statistics extracted from the “National Strategy for Circular Economy,” a strategic positioning document prepared by the Ministry of Environment and Economic Development.

Here some interesting statistics:

- Domestic material consumption amounts to ten tons per capita, among the lowest values within the G7 countries and the European Union.

- Resource imports have decreased from 225 million tons in 2005 to 155 million tons in 2015.

- Waste production in 2015 totaled 159 million tons, with 29 million tons being municipal waste and 130 million tons classified as industrial waste. This figure has remained relatively stable in recent years, indicating an increase in recyclable materials suitable for recycling processes.

- Secondary raw material production from urban separate collection was 10.6 million tons in 2014, an increase of 2 percent in 2015. This figure should be compared with the 15.6 tons of material recovered. Doing a quick ratio, about 70 percent of the materials are put back into the market.

Dl 116/2020 integrating the European EC package of 2015

With the implementation of the Circular Economy Package, launched by the European Commission in 2015, Italy enacted legislative decree number 116 in 2020, which brings the new European directives to the national level.

In particular, this new decree partially amends other existing regulatory texts, such as Legislative Decree 152/2006, also known as the Consolidated Environmental Act (TUA).

The following is a bulleted list of the main changes introduced in waste management for producers, highlighting the key points:

- Termination of waste qualification

- Obligations for proper waste management

- Packaging labeling

- Waste traceability system

- Waste classification

- Waste management

The new strategic program for Circular Economy in Italy

On June 24, 2022, Minister of Ecological Transition (MiTE) Roberto Civolani signed two important decrees:

- Approval of the “National Strategy for Circular Economy”

- Adoption of the “National Program for Waste Management”

The Ministerial Decree (DM) of June 24, 2022, No. 259 is of utmost importance as it anticipates the deadline, set by the EU Commission for June 30, 2022, to achieve Mission 2, Component 1, Reform 1.1 of the National Recovery and Resilience Plan (NRP).

This area of the NRP is specifically related to the green revolution and ecological transition, with the primary aim of addressing ongoing climate change.

Goals of DM June 24, 2022:

DM’s goals are:

- Introduce a new digital waste traceability system, partly realized through the implementation of the new National Electronic Registry for Waste Traceability (RENTRI).

- Provide tax incentives to support recycling companies and the use of secondary raw materials (MPS).

- Undertake a comprehensive revision of the environmental waste tax system to make recycling more convenient and attractive compared to traditional and impactful disposal practices such as landfilling and waste-to-energy.

- Ensure the right to reuse and repair, including long-lasting and repairable products, with improved labeling and extended warranty.

- Reform the EPR (Extended Producer Responsibility) system and Consortia to meet the thresholds set by the EU, including the establishment of a specific supervisory body under the MiTE.

- Development/Update of End of Waste (EoW) regulations, which encompass the recovery processes applied to waste with the aim of transforming it into new valuable material for other businesses.

- Development/Update of Minimum Environmental Criteria (CAM), which represent the minimum environmental standards to be met when purchasing products and services by the Public Administration (PA) and for tender procedures.

Turn your company waste into value

Sfridoo® empowers you to harness the residual value of your waste, enabling you to achieve economic, fiscal, and environmental benefits. Embrace the principles of the Circular Economy and collaborate with other companies in our network to maximize your gains.

enhance value nowIndicators for Circular Economy

Over time, there have been continuous efforts to create tools for measuring the impact and extent of the changes brought about by Circular Economy in our society.

Indicators are the primary tools used to address this need, quantifying the circularity of companies, municipalities, territories, districts, nations, and markets.

Just like other aspects of Circular Economy, there are both national and international indicators developed by various entities, including institutions, organizations, foundations, and private structures.

Foreign Indicators

Foreign indicators for Circular Economy come in various types and serve different purposes.

Let’s explore them together:

- Circulytics – an indicator developed by the Ellen MacArthur Foundation (EMF) to support companies in transitioning to circular systems, regardless of industry, structure, or size. This comprehensive indicator provides valuable insights for enhancing business management.

- Material Circularity Indicator (MCI) – devised through collaboration between EMF and Ansys, an innovative engineering and smart material design company. This tool is designed to improve product design and raw material sourcing.

- Global Reporting Initiative (GRI) – an internationally recognized indicator that provides guidelines for companies to prepare sustainability reports, taking into account the economic, environmental, and social impacts of production processes.

- Circular Transition Indicators (CTI) – a tool developed by the World Business Council on Sustainable Development (WBCSD) with the aim of accelerating the transition to a more sustainable world and enhancing the effectiveness of sustainable businesses.

- Circular Metrics for Business – a report created by the nonprofit organization Circle Economy, encompassing three types of metrics: leading indicators, performance indicators, and process indicators.

- Circle City Scan Tool – a tool developed by the nonprofit organization Circle Economy, designed to assist cities and regions in developing operational plans for Circular Economy, providing local authorities with opportunities applicable to their areas.

- CirculAbility Model – a tool created by the Enel Group to measure the circularity of companies, considering all the fundamental pillars of Circular Economy.

Italian indicator

A new specific UNI standard, UNI/TS 11820 “Measurement of Circularity – Methods and Indicators for Measuring Circular Processes in Organizations” came into effect in November 2022 at the Italian level.

The legislative process that led to its creation involved approximately 85 organizations, with almost half participating in the testing phase to refine and consolidate the method’s functionality.

The complete version of UNI 11820 encompasses 81 circularity indicators, categorized into 6 groups: material and component resources, energy and water resources, waste and emissions, logistics, products/services, human resources, assets, policy, and sustainability.

This specification is applicable to any organization involved in the provision of products and/or services and can be implemented on various scales: micro level (individual organizations), meso level (groups of organizations, industrial clusters, municipalities, cities), and macro level (regions, countries).

The new UNI standard serves a dual purpose. Primarily, it aims to measure organizational circularity, while also monitoring progress and improvement over time.

Pros and Cons of Circular Economy

As any other sector, the Circular Economy has its positive and negative aspects. It follows the same business patterns as other industries, facing daily challenges and leveraging its strengths for benefits.

The Circular Economy, which focuses on sustainability, highlights how innovation and limited awareness of available tools can lead to untapped opportunities due to bureaucratic complexity.

Benefits of Circular Economy

Here are some advantages that companies can derive from applying principles, frameworks, and models of the Circular Economy:

- Reuse of objects, which helps avoid the loss of their value and saves embodied energy, the energy expended in their production.

- Establishment of symbiotic and regenerative industrial relationships, minimizing significant environmental impacts.

- As the implementation of such systems increases, it generates job opportunities and fosters the emergence of new professions (e.g., green jobs).

- Promotion of business networking, expanding opportunities for collaboration and the sharing economy.

- Reduction of costs associated with production processes, particularly by utilizing recovered/recycled materials and substances to manufacture high-performing objects.

- Lower costs related to the disposal of production residues.

- Reduced environmental impact is achieved by utilizing renewable energy in production processes and incorporating reusable or recycled resources within products.

- There is a decrease in the quantity of production residues due to product design that focuses on the recovery and reuse of individual parts at the end of their life cycle.

- Production efficiency is improved by adopting innovative and efficient technologies.

- Waste is minimized through the implementation of “reverse logistics” programs that recover products from the market, regenerate them, and reintroduce them into circulation.

Barriers to Circular Economy

As mentioned earlier, the disadvantages associated with this sector are primarily related to three factors: company awareness, technical and bureaucratic aspects of processes, and the state of technology development.

When discussing Circular Economy, it is not accurate to speak of actual disadvantages. Instead, it is more appropriate to consider states or conditions that hinder the diffusion of these new paradigms among the population.

Starting with the first disadvantageous condition, it is crucial to highlight the lack of a suitable mindset among companies, individuals, and institutions. There are still too many entities that are either unaware of or unwilling to recognize the potential of this sector.

The second major barrier is the bureaucratic complexity, which tends to be confusing and inflexible. However, it is worth noting that there have been interesting updates in regulations in recent years, aiming to modernize the approach.

The final significant disadvantage is associated with the types of technologies employed at both the product and process levels in this sector.

Apart from the inherent limitations of raw materials, there is currently a scarcity of products in the market that are developed using an ecodesign approach and, consequently, are not sustainable. Moreover, with regard to processes, the main obstacle lies in the maintenance costs, which are not currently comparable to those of traditional processes.

Concrete Examples of Circular Economy

Circular Economy is often mistakenly perceived as a sector characterized by theoretical concepts rather than practical substance, leading to the misconception that its implementation is challenging and unprofitable.

On the contrary, a brief market research demonstrates a completely different scenario, showcasing numerous successful companies in this sector that are actively promoting new products and services.

This group comprises startups, small and medium-sized enterprises (SMEs), multinational corporations, and other entities that share a strong commitment to change and innovation, driven by new business opportunities.

Circular Economy Business Cases

Below is a list of case studies from various sectors, which are also extensively covered on the Sfridoo Blog.

Cases Studios are:

- Progetto papillon di Bosh, a service based on the rental of home appliances, devised by the German multinational company Bosh.

- Kalundborg, one of Europe’s first and most significant eco-parks for industrial symbiosis, located in Copenhagen and established in the 1960s.

- MoBike, a leading Chinese company in the sharing economy that introduced its bike-sharing service.

- Caterpillar, an American giant in the machinery manufacturing sector that internally implements activities for remanufacturing and reconditioning mechanical parts of its products.

- Google Stadia Project, developed by Google itself, with the aim of revolutionizing the gaming industry through Circular Economy and the PaaS business model.

- Ikea, the renowned home furniture chain that launched its furniture rental service.

- Fairphone, a young company producing ethical smartphones made from fair trade materials.

- Pampers, q brand owned by the Procter&Gamble holding company, which launched an innovative diaper recycling project using specialized containers.

Circular Economy Startups

In addition to the established and well-structured companies mentioned above, there is another market segment consisting of innovative and sustainable startups that emerge every day with the ambition to revolutionize specific industries. Here are some inspiring case studies:

- Loop, an American platform focused on reusing retail packaging for product sales.

- I-kasa, a Japanese startup that operates on an umbrella rental business model.

- Grover, a A German startup that offers a subscription service for electronic products.

- Fortunale, an Italian startup that produces and sells 100% organic wool sweaters.

- Viridi, an Italian company founded in 2016, dedicated to making weddings sustainable through specialized services.

- Lexup, a startup aiming to digitize the legal sector by providing innovative ways to study and stay updated on legal matters.

- Trebo, an innovative startup that transforms beer waste, known as “trebbie,” into bakery products.

- Origami, startup that turns milk waste into lanital, an innovative fabric with very special characteristics.

- Chainable, a A Dutch startup that provides kitchen rental services.

Circular Economy Resources

Regardless of your background, whether you are an industry professional, novice, student, or researcher, the first crucial step is to start studying Circular Economy from a theoretical perspective. Understanding the concepts is essential to effectively implement them and anticipate potential challenges. Here are some recommended resources to deepen your knowledge in this ever-evolving field.

Circular Economy Books

When it comes to the academic approach, books are the first thing to start from.

In this context we are not talking about books intended as manuals, but rather literary works written by experts, full of food for thought and valuable practical advice.

You can find several resources on the web that contain valuable reading advice. Below, to facilitate your learning, here are the five essential books for gaining an understanding of the dynamics of this field:

- What is Circular Economy – Emanuele Bompan

- Circular economy. From waste to value – Peter Lacy, Jakob Rutqvist e Beatrice Lamonica

- A world without waste? Journey into circular economy – A. Massarutto

- Neo Materials in Circular Economy – A. Pellizzari, E. Genovesi

- Circular economy for everybody – W. R. Stahel

Courses on Circular Economy

Another type of training undoubtedly includes courses. In this case, there are various types of courses that differ in duration, level of module depth, mode of availability (online or in-person), and the institution that provides them.

Master’s Degree on Circular Economy

The training paths present within Italian universities are, at the time of writing:

- Circular Economy Management – Liuc Business School.

- Strategic management of the circular economy – ALTIS Unicatt

- Circular Economy – University of Tuscia

- Circular Economy Management – Luiss Business School.

- Ecological Transition Management – UNIMORE.

- Sustainability & Circular Economy – Bologna Business School.

- Circular Economy and Sustainability Management – Sapienza University of Rome

More courses on the Circular Economy

The most interesting training paths made available by companies or other entities are:

- The Circular Economy – Udemy.

- LifeGate Education – LifeGate.

- Massive Open Online Course – TU Delft.

- Certificates and Training – Circular Economy Club.

- Tool Box – Circular Academy.

- A Circular Economy of Metals – Coursera.

- Circular Economy Courses – edx.org.

- Digitalization for Circular Food Systems – eitfood.eu.

- Circular Economy and the 2030 Agenda – United Nation System Staff College.

Turn your company waste into value

Sfridoo® empowers you to harness the residual value of your waste, enabling you to achieve economic, fiscal, and environmental benefits. Embrace the principles of the Circular Economy and collaborate with other companies in our network to maximize your gains.

enhance value now